Size Matters

Most NZ councils will only allow up to 10m² of floor area and up to 3.5m of height above the floor level before you require a permit. Check with your local council on what is allowed in your area. If you have a Body Corporate / Cross-lease or live in a Historic area you should check on that too.

Permits may mean a resource consent plus building consent, this can be time consuming and costly. Height to Boundary rules – Usually a shed is meant to be the height of the wall away from the boundary (“height to boundary”). If you are wanting to put the shed on or closer to the boundary than this you should first check with your neighbour, and the council.

Things to Consider

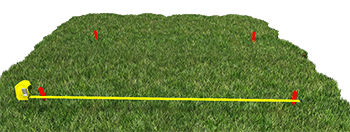

Measure up the space with a tape measure..

What size shed can you fit in the space?

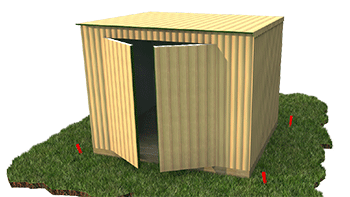

Is there room for a door to swing out?

You may be able to change the doors location to fit depending on whether the type of shed is customisable.

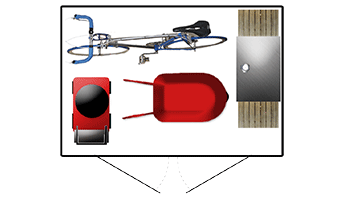

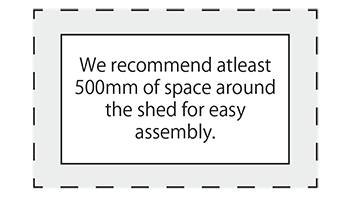

How much do you want to store in the shed / how much room do you need for a workshop?

Sometimes it helps to mock it up on paper.

Consider roof overhang, not just floor size – most sheds have a roof overhang, at least on the front.

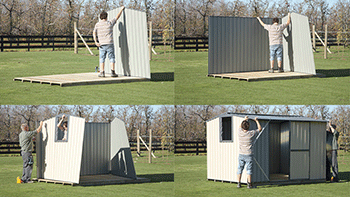

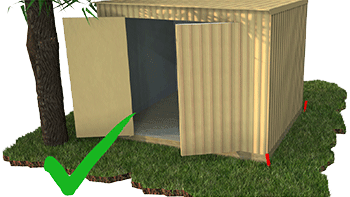

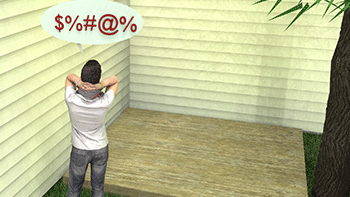

Consider that you may need some room to move around the shed in order to assemble it. Room to swing a hammer/wield a power drill on all four sides makes assembly much easier!

There are alternative assembly options for tricky & tight spaces that will need to be discussed.

Is it big enough? We often get people coming back for another shed because they have filled the first, we have not heard the complaint, “the shed is too big”

Location, location, location

Things to Consider

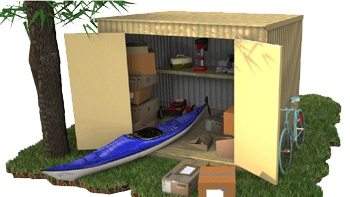

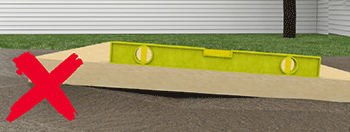

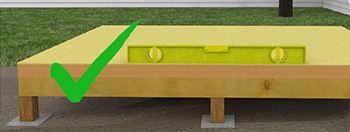

Is the site clear, flat, level & free draining?

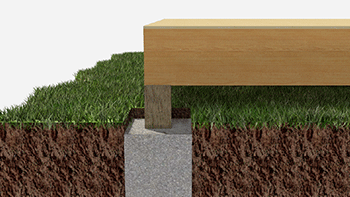

If not you may require foundations to put the shed on – this could be a DIY job or something a builder could do for you

(Gubba Garden Sheds have expert builders who do this work every day)

Is the site coastal or exposed to strong winds?

Wooden sheds and timber framed sheds are generally better than sheds with no framing for windy areas.

Zincalume protected steel is better than galvanised for corrosion resistance, especially in salty and geothermal areas. Coloured steel generally adds another layer of corrosion resistance (paint / powder coating) to the steel, but it pays to check on what the steel is protected with regardless of whether it is coloured or not.

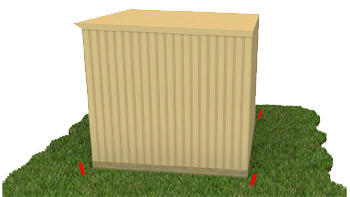

Ground Fastenings

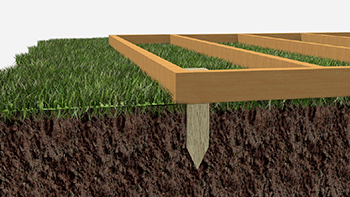

Even in a sheltered location your shed should be secured to the ground.

Sheds have been known to blow away in a cyclone etc.

Piles in concrete

Ground pegging

What’s it’s purpose?

If you want a shed to use as a workshop you may have different requirements to than a shed to use for storage.

Some sheds are great for storing garden tools, but less suited to storing house hold items.

Steel sheds can condensate moisture on the inside of the shed if the base is not dry. Often lining the shed with building paper will help with this.

Timber sheds are better insulated and usually have building paper as a standard option

Ventilation is required to keep a shed dry – most sheds will have small gaps where the ridges in the roofing allow air in, this is very useful to help the shed breathe and prevent dampness

Steel with wooden framing

Steel framed sheds

Timber sheds

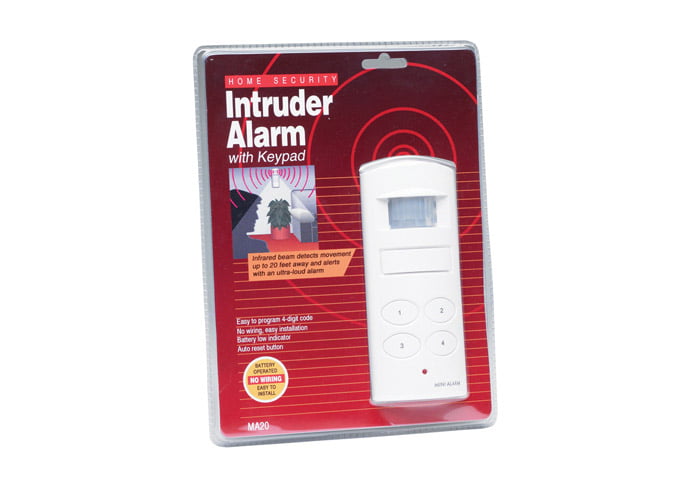

Sheds have varying levels of security, if you have high value items that you want to store in the shed there are options to increase the security / make a shed

harder to break into. However they are simple structures, not Fort Knox!

Who will assemble it?

All our sheds are supplied with step by step assembly instructions, written by

kiwi’s with years of experience. Imported shed instructions may not be very clear.

WARNING: Most sheds have steel sheets, the edges of steel can be very sharp.

Please wear gloves when handling steel, do not try to assemble on a windy day and take usual safety precautions, make sure you are working on a stable platform, do not stand on the top of a ladder, and get someone to help you hold things.

People have injured themselves by not following simple safety practices

If you have not assembled a shed before it can be more of a task than you

expected, with a small shed often taking a first timer a whole day to install.

If you are not a DIY type we can help with tips and advice, or organise the whole thing from the ground up.